About Permanent Magnet Synchronous Motor

- Constructions and types- (IPM) internal permanent magnet

- Working principle - the rotation of the field gets synchronised with the rotor, consequently there is zero slip in the field. The RPM is constant, depending upon the input command

- Permanent magnet synchronous motor control

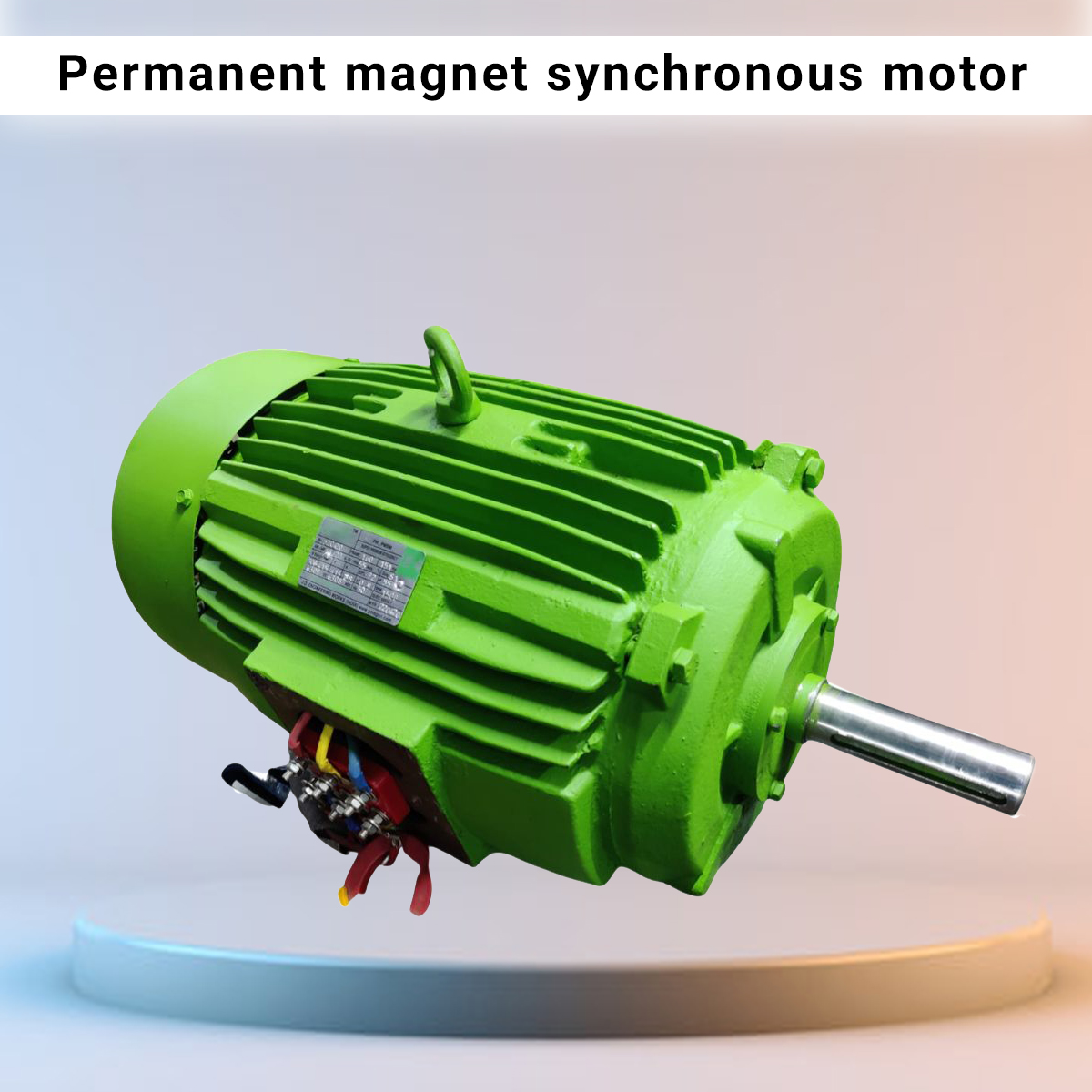

The Permanent Magnet Synchronous Motor (PMSM) is also called AC synchronous motor and IE4 or Super High Efficient Motor where the field is excited by permanent magnets that generate sinusoidal back EMF. This unique magnetic motor harnesses magnetism to create continual motion. So what this suggests is that after the motor starts it'll pass by itself and while the magnets maintain their polarity, the motor will never stop running.

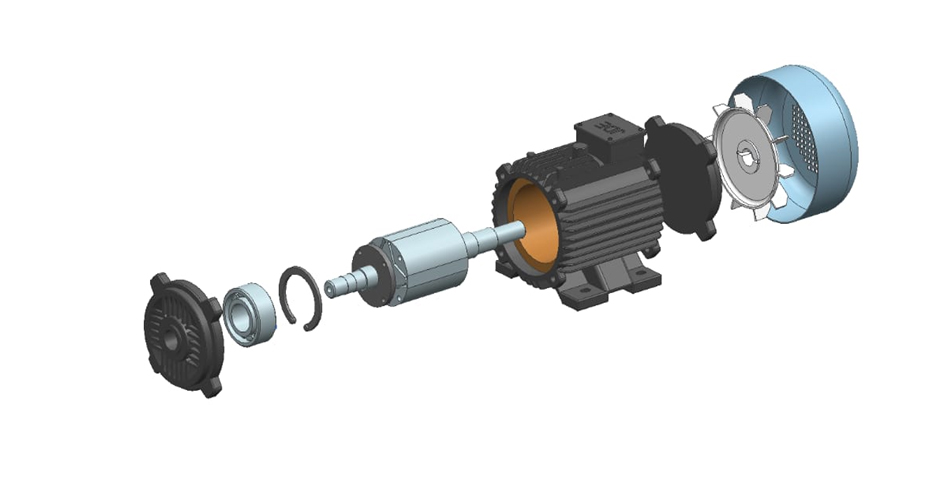

Synchronous Permanent Magnet Alternator contains a rotor and stator same as that of an induction motor but a static magnet is employed as a rotor to form a field. The PMSM is an alternate to induction motor or AC motor. It’s widely utilized in industries, or to run the equipment. 20-25% increases when PMSM is employed as another to Induction Moto.

Some of the advantages of asynchronous static magnet motor include: provides a gentle and consistent flow of free electricity, it's environmentally safe as no gases or chemical emissions is released, it works in extreme cold and extreme heat indoors and outdoors, it's small and cheap to create, and therefore the maintenance level is extremely low.

The magnets inside a synchronous magnet motor create a rotation motion which is largely K.E. This energy is often converted into voltage for your household by attaching the axle of the wheel to a DC motor. With the DC motor, the electrical energy can then be moved to the battery that stores it until it's able to be used for your household needs.

The synchronous permanent magnet motor is closely associated with motion. The motor will run indefinitely producing a greater amount of energy than it uses. This suggests that it generates free energy indefinitely and runs by itself without the requirement of a 3rd party device or resource to power it. The motor will power itself on any source of renewable or non-renewable energy. It powers itself and produces energy on its own while not having alternative energy, heat, water, or coal.

If you guys struggling hard to find out the reputed PMSM Motor Manufacturer in India, then without any second though you can choose J.D. Engineering Works. It’s a leading organization it’s a number one organization recognized for the look and development of the most advanced motor. All products are manufactured with prime quality material as per industry standards at the company’s large-scale manufacturing facility. Wide selection of products for various applications makes an effect and seems to be the primary choice of shoppers thanks to extremely efficient, cost-effective, compact in size, rugged, and industry pertinent attributes.

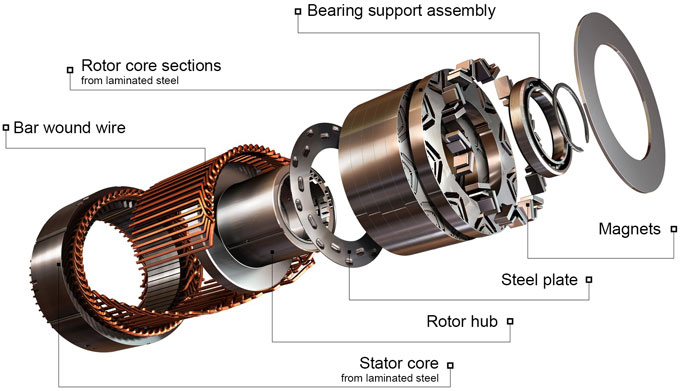

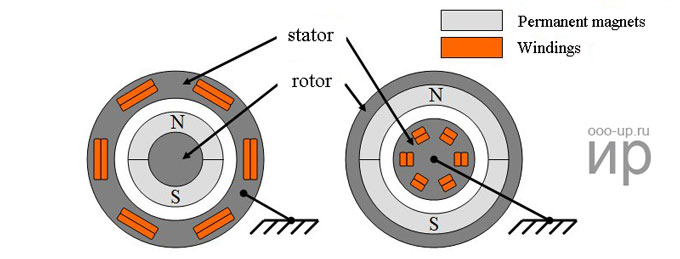

Typically, the rotor is located inside the stator of the electric motor, there are also structures with an external rotor - inside out electric motors.

Constructions of a permanent magnet synchronous motor: on the left - standard, on the right - inside out.

The rotor consists of permanent magnets. Materials with high coercive force are used as permanent magnets.

According to the rotor design, synchronous motors are divided into:

• electric motors with salient pole rotor;

• electric motors with non-salient pole rotor.

Working Principle of PMSM:

Now you're visiting know the working rule of magnet electric motor that's same as that of electric motor. When three phases of winding of the stator are energized from 3 phase supply, the rotating field is about up within the air gap. At synchronous speed, the rotor field poles lock with the rotating magnetic flux to supply torque, and hence rotor continues to rotate. As we all know that electric motor isn't self-starting, PMSM must be started somehow. Since there's no winding on the rotor, induction winding for starting isn't applicable for such motors and so variable frequency power supply for this purpose.

Permanent magnet electric motor (PMSM) discovers a big selection of business applications thanks to low power consumption and enhanced performance competencies. Improved torque utilization with the fast-changing speed and electric stability with guaranteed consistent performance leads PMSM to be the mandatory choice of business applications. A magnet electric motor (PMSM) is often thought of as a hybrid mixture of a brushless DC motor (with relevancy to the rotor) and an AC induction motor. PMSMs offer high efficiency, a high power factor, a high torque-to-weight ratio, faster response times, rugged composition, are fairly easy to regulate, and are straightforward to keep up.

Advantages of PMSM:

The static magnet electric motor, observed as PMSM, is an AC motor. Its stator runs with three-phase difference electricity, while its rotor may be a magnet. The most important advantage of this sort of motor is that the AC power is provided by DC so that the motor may be accurately controlled and therefore the life problem caused by the comb is solved.

1. The motor is tiny in size and light-weight in weight: In recent years, with the continual application of high-performance magnet materials, the ability density of magnet synchronous motors has been greatly improved. The output torque of static magnet synchronous motors under the identical volume is about 1.7 times that of induction motors.

2. Wide speed range: The magnet electric motor supported the special structure design can adopt the most torque/current control strategy during constant torque operation and adopts the sphere weakening control strategy during constant power operation, which might obtain good speed regulation operation characteristics, and successfully achieved over 5 times the sphere weakening speed range.

3. Small moments of inertia, high acceleration are often obtained, and good dynamic performance.

4. Large overload capacity: The rotor of a static magnet electric motor has no slippage. When rigid processing is meted out, there'll be no surface effect processing abnormality caused by speed fluctuation.

All the above information about PMSM is extremely helpful. If you're looking for a Permanent Magnet Synchronous Motor Manufacturer in India, then directly reach J.D. Engineering Works. We are a trusted global authorized distributor of semiconductors and electronic components. We specialize in the rapid introduction of the most recent products and technologies targeting the look engineer and buyer communities. Our global distribution center is provided with state-of-the-art wireless warehouse management systems that enable us to process orders 24/7 and deliver nearly perfect pick-and-ship operations.